Wash with soap and water mini flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is located inthe Shanghai Songjiang industry zone, which is a famous enterprice forresearch,produce,sales and service of flow meter, registered capital of 11million RMB. Main products:mirco flow meter,oval gear flow meter ,piston flow meter,gear flow meter,gearpump,mass flow meter. Products with superior performance, excellent qualityhas been the various professional certification and customer recognition. Thecompany has a number of fluid measurement equipment experts and various typesof senior engineer, continuous development and manufacturing, upgradingproducts are available every year.

Wash with soap and water mini flow measurement

Ovalgear flow meter is widely used inpetroleum, chemical and hydraulic industries due to its advantages of highprecision, simple installation, stable performance and goodrepeatability.However, the Oval gear flow meter that can be produceddomestically can only be applied due to the impatience of high pressure In thelow pressure occasion, the high pressure measurement occasion can only rely onthe foreign imported high pressure flowmeter.Therefore, the research of thehigh pressure Oval gear flow meter will help to expand the domestic applicationof the Oval gear flow meter and promote the development of the domestic flowmeasurement. Deep instrumentation independent research and development of the Ovalgear flow meter pressure up to 1000bar, it can be said has reached a higherlevel in the world, and obtain measurement certificate.

TheCX-M and G-series mirco flow meters are the world"s new volumetric flowmetersintroduced by BASF in 2011. Since its establishment, the CX-M oval gear flowmeter and the G-series mirco flow meters have been selling well in the marketfor more than 100,000 units a year since they were sold. The third generationlaunched in 2017, with more than 90% accuracy and stability, won thecertification of the National Bureau of Metrology. The quality and reliabilityof Shanghai JiShen instruments need not worry. According to the statistics ofChina Instrument Association, Deep flow meter reliability has always beenranked in the top 3, especially in the long-term statistics failure rate is farbelow the industry average, deep advocate "the best after-sales service isno service", but also achieved a continuous three years without qualitycomplaints .

Wash with soap and water mini flow measurement

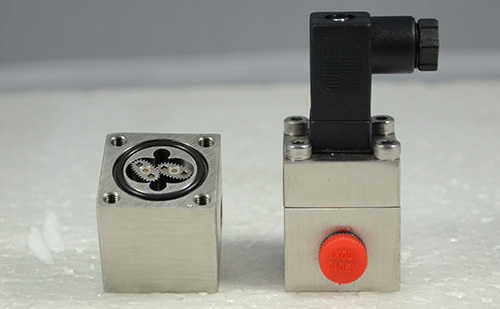

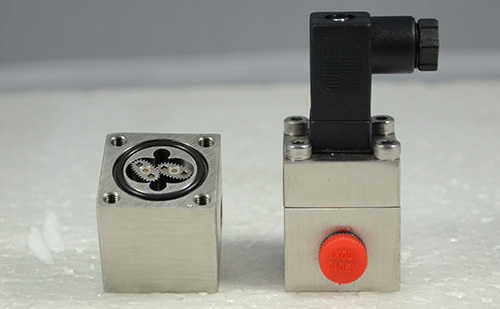

The measuring part of Oval gear flow meter mainly consists of twointermeshing gears and their housings, and the gear generates the acting momentto make it rotate under the pressure difference of the measured medium. Thegears alternately rotate with one another to drive the measured The medium inorder to half the volume of the unit from import to export row by row, so themirco flow meter discharge per revolution measured volume of medium is half thevolume of 4 times the volume flow through the micro-volume flow meter Q Can befigured out

Wash with soap and water mini flow measurement

Maintechnical data of JSN micro oval Oval gear flow meter

CX-M2,flow range :0.5~150ml/min,accuracy 0.5%,G1/8"

CX-M3, flowrange:3~300ml/min,accuracy 0.5%,G1/8"

CX-M5, flowrange:5~1000ml/min,accuracy 0.5%,G1/8"

CX-M6, flowrange:0.5~100L/H,accuracy 0.5%,G1/4"

CX-M9, flowrange:6~600L/H,accuracy 0.5%,G1/4"

CX-M12,flow range:0.3~30L/Min, accuracy 0.5%,G1/2"

CX-M25,flow range:0.5~100L/Min, accuracy 0.5%,G1"

What are the precautions for the gear flow meter?

1) If the medium temperature is too high, or the pressure is too high, please inform us before purchasing, we can customize it for you.

2) When the pipeline is continuously operated and the flowmeter is to be installed in a horizontal pipeline, a bypass pipeline should be installed to facilitate cleaning and overhaul; when the flowmeter is installed on a vertical pipeline, the flowmeter should be installed on the bypass. In the pipeline, to prevent debris from falling into the instrument. When the fluid flows from bottom to top, the vertical tube in the upper part of the flowmeter should be as short as possible to reduce the precipitation of impurities in the upper piping.